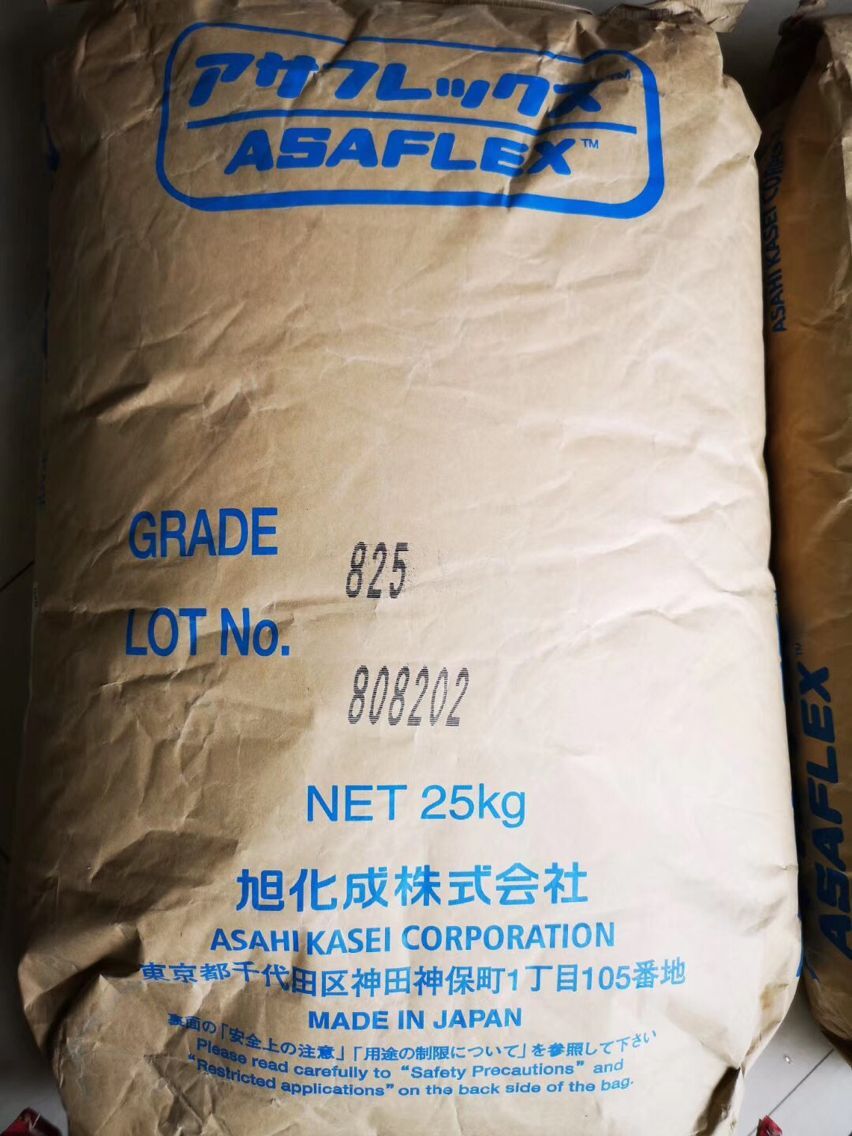

日本旭化成 SBC Asaflex 805 符合食品級(jí)K膠 高流動(dòng) 高透明

Clear Styrenic Block Copolymer (SBC) Asaflex? 805

Asaflex? 805 has high flowability and high transparency. Suitable for injection molding

Applications

- Footwear

- Medical

- Transparent Molded Products

Physical Form

- Pellet

Features and Benefits

- High flowability

- High impact resistance

- High transparency

Regulations

- FDA CFR 177.1640

- Regulation (EU) No 10/2011

- USP Class Ⅵ

Characteristics

| Property | Test Method | Unit | Value |

|---|---|---|---|

| Density | ISO 1183 | g/cm3 | 1.02 |

| Water Absorption | ISO 062 | % | <0.1 |

| MFR 200°C, 5kg Load | ISO 1133 | g/10 min | 10 |

| Mold Shrinkage | – | % | 0.2~0.8 |

| Tensile Strength, 50 mm/min | ISO 527-1 | MPa | 33 |

| Elongation, 50 mm/min | ISO 527-1 | % | 30 |

| Flexural Strength | ISO 178 | MPa | 50 |

| Flexural Modulus | ISO 178 | MPa | 1550 |

| Rockwell Hardness | ISO 2039-2 | – | HRR 68 |

| Durometer Hardness | ISO 868 | – | HDD 75 |

|

Charpy Impact Strength* Unnotched |

ISO 179 | kJ/m2 | 16 |

|

Charpy Impact Strength* V-notched |

ISO 179 | kJ/m2 | 1.3 |

|

Heat DistortionTemp. Non-annealed,1.8 MPa load, 120 K/h |

ISO 75-1 | °C | 63 |

|

Vicat Softening Point 10 N Load, 50 K/h |

ISO 306 | °C | 91 |

| Total Light Transmission, 2mm Thick Plate | ISO 13468 | % | 90 |

| Haze, 2mm Thick Plate | ISO 14782 | MPa | 0.5 |

簡(jiǎn)繁切換

簡(jiǎn)繁切換